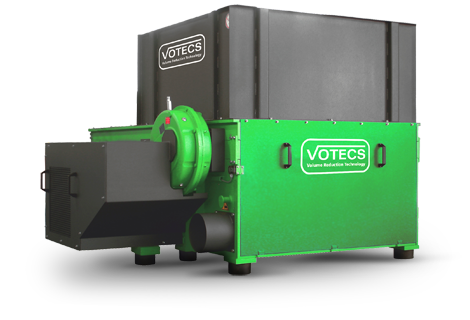

VOTECS shredders have for years been installed in trade and industrial operations for economical processing of wood wastes and many other materials. The machines are characterized by their robust technology and consequently reliable operation. VOTECS shredders are optimally designed for customer's specific tasks. The machines guarantee a trouble free shredding process with high energy efficiency.

Particular characteristics are:

The shredder operates very quietly and dust free: The material to be shredded is firstly deposited

into a large hopper. Via a hydraulically controlled pusher it is then pressed against

the cutting rotor. The shredding of the material occurs between a rotor shaft and a fixed opposing

knife.

The pusher‘s feed rate is controlled directly and is dependent on the power consumption

of the main motor. The fixed screen, located underneath the rotor, determines the desired

shavings size. After shredding optional transportation of the shavings takes place

via an extraction unit, a screw conveyor or a conveyor belt.

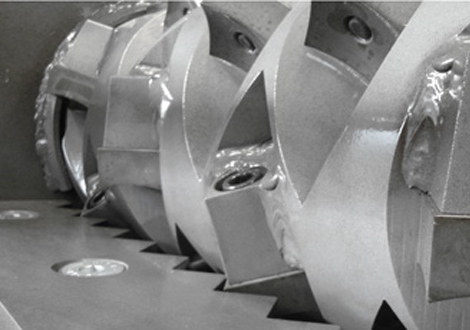

The new cutting system VOTECS the

total package:

Fixed rotors – Customized rotor diameters

The rotors are manufactured from one piece and for this reason they are particularly torsion

resistant. Specially manufactured knife holders are welded around the circumference

of the profiled rotors. The quadruple rotating rotor knives are screwed into this from behind

whereby optimal damage protection of the screw heads as well as faster knife changes

are made possible. Different rotor diameters (252, 368, 462 und 600 mm) are available

each according to application purposes.

Standard equipment

The illustration shows cutting chamber with 2 cutter shafts and 2 spacer shafts

Options:

The material is fed to the rotor horizontally through a hopper, roller feed, or vibrating channel feeder. The shredders are especially used for shredding longer wood waste. The VHZ-L and VHZ-B series shredders can be used directly next to wood processing machines because of their compact design.